Sheet metal working

State-of-the-art machinery and qualified specialists ensure consistently high product quality.

All classic manufacturing processes are used when processing sheet metal of different materials in thicknesses from 0.1 to 25 mm and sheet formats up to 3,000 x 1,500 mm. The size of the manufactured parts ranges from the millimetre range to assemblies with dimensions of 4,800 x 3,800 x 15,000 mm, as well as weights of 10 tonnes.

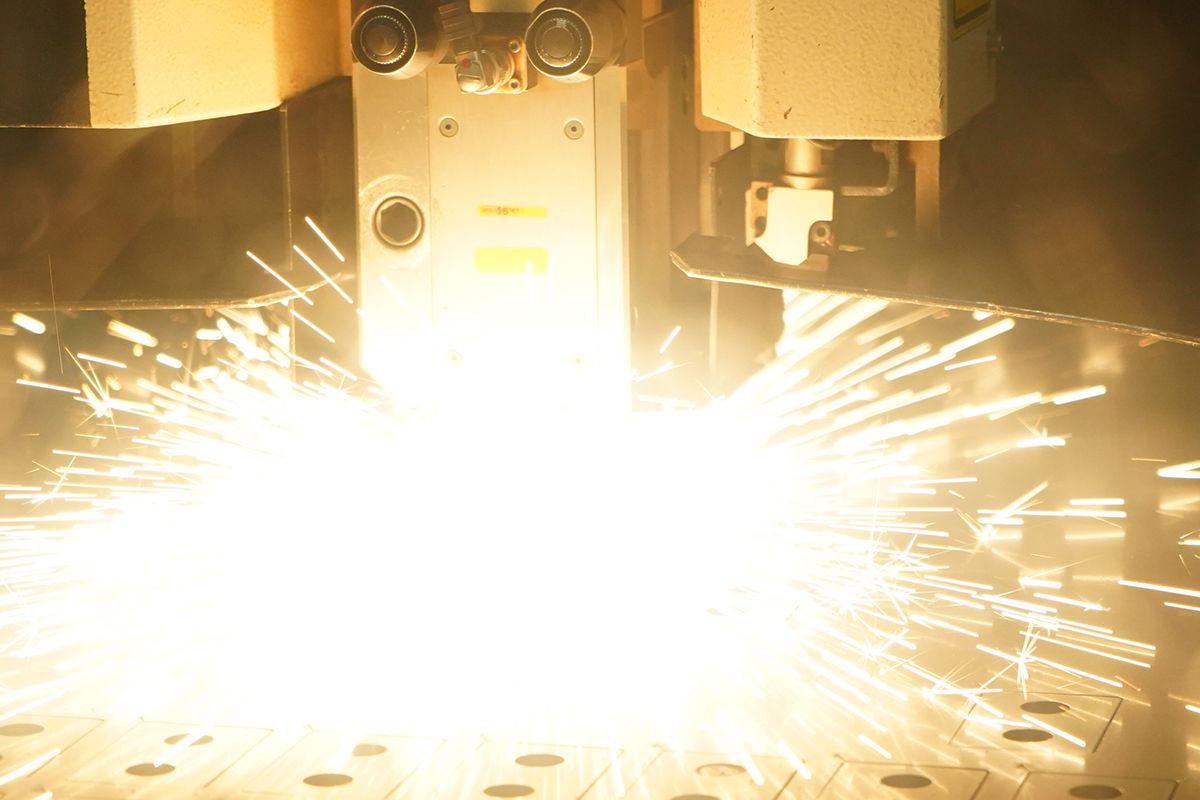

Laser cutting is used by us where complex two- or three-dimensional, precise contours have to be produced. With our production systems from the market leader Trumpf, we are able to produce three-dimensional apertures without contact and almost without force, even in places that are difficult to access.

Flatbed lasers enable a fast cutting speed and the highest cutting quality. They thus ensure the greatest flexibility and design possibilities. Compared to alternative processes, such as punching or nibbling, laser cutting can be used economically even for very small batch sizes. The direct connection to the fully automatic high-bay warehouse ensures an uninterrupted material supply around the clock.

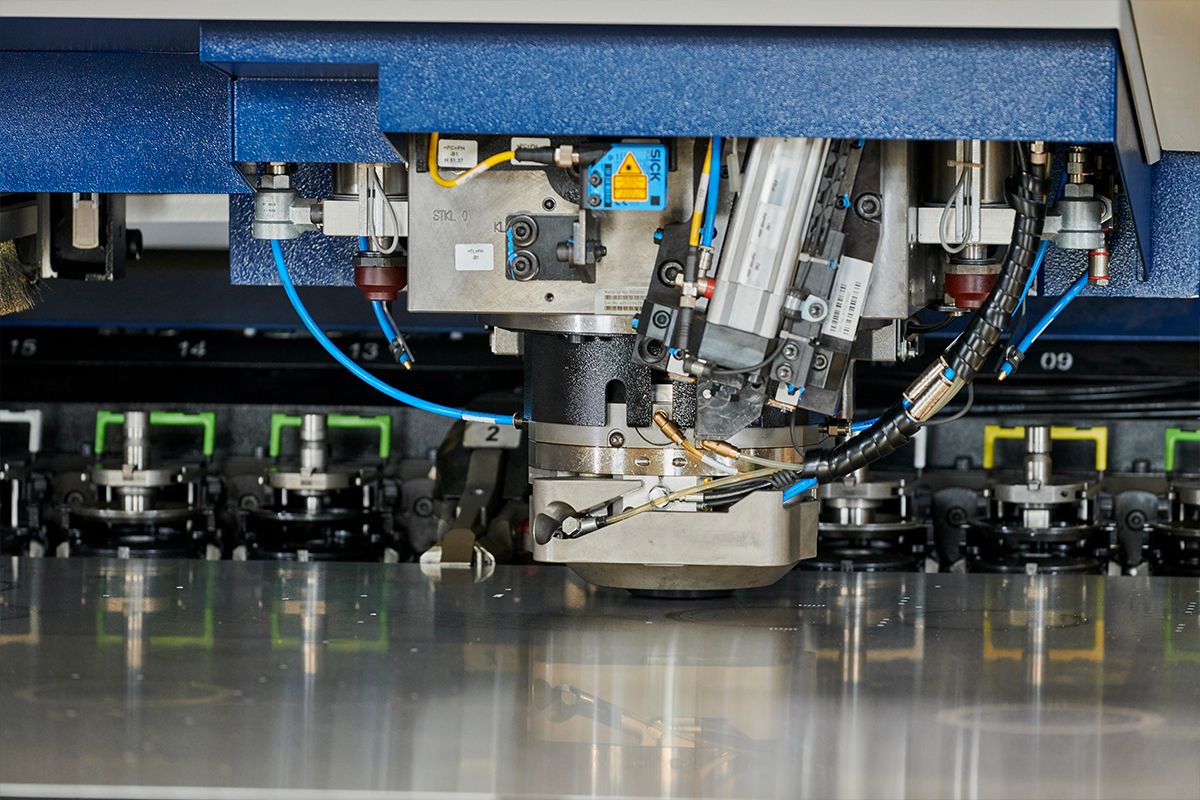

Combined production systems for best quality

In order to combine the advantages of laser cutting with those of punching and nibbling, we use combined production systems that allow operations with the punching head as well as the laser cutting of any contours. With a variety of punching tools for the desired machining in the best quality, we combine machining with the laser. Your advantages are higher processing speed, lower punching forces and reduced energy consumption.

In forming by die bending or folding, the sheet metal is pressed into a V-shaped lower tool by a controlled downward movement of the upper tool, forming it in a straight line. Stops ensure the exact position of the workpiece.

CNC-supported press brakes with up to 3,200 kN pressing force and a maximum bending length of 4 metres are used to shape sheets up to 20 mm thick. Our handling robot ensures high efficiency and repeatability in the production process.